HEAT EXCHANGER DESIGN Ramesh K. Shah Rochester Institute of Technology, Rochester, New York. 3.7.1 Log-Mean Temperature Difference, LMTD 186 3.7.2 Log-Mean Temperature Difference Correction Factor F 187 3.8 F Factors for Various Flow Arrangements 190 3.8.1 Counterflow Exchanger 190. The picture seems to show a heat-driven fan system. There’s a flare of metal fingers behind the fan blade, which looks like a “heat sink” commonly used in electronics. I deduce that the heat rising from the metal stove top goes up through the leg of the fan and out through the heat sink, or rises through the air and into and through the heat sink.

Best Shed Plans Plans to Making Diy Wood Boiler Plans PDF Download

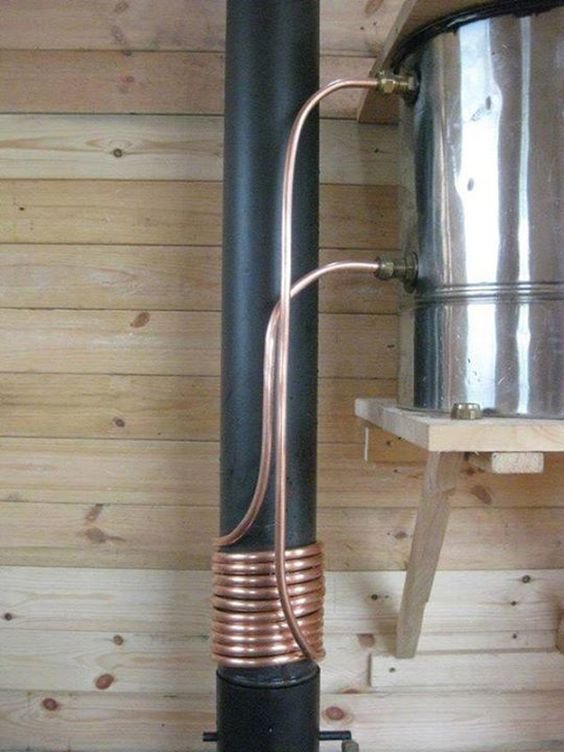

Make a wood stove water heater outdoorwood Wood stove water heater, Rocket stoves, Survival

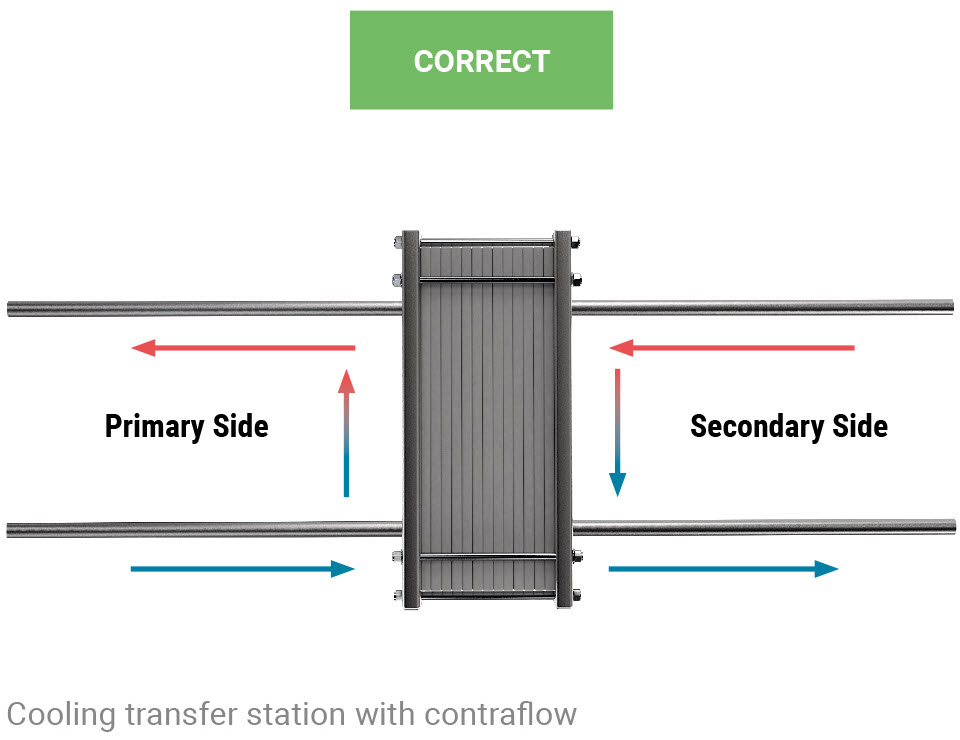

Heat Exchangers

Heat Exchanger

(PDF) HEAT TRANSFER LOG MEAN TEMPERATURE DIFFERENCE (LMTD) METHOD Parallel Flow Heat Exchanger

plateheatexchanger Belimo

HRS Process Systems Ltd., Pune, Plate Heat Exchanger

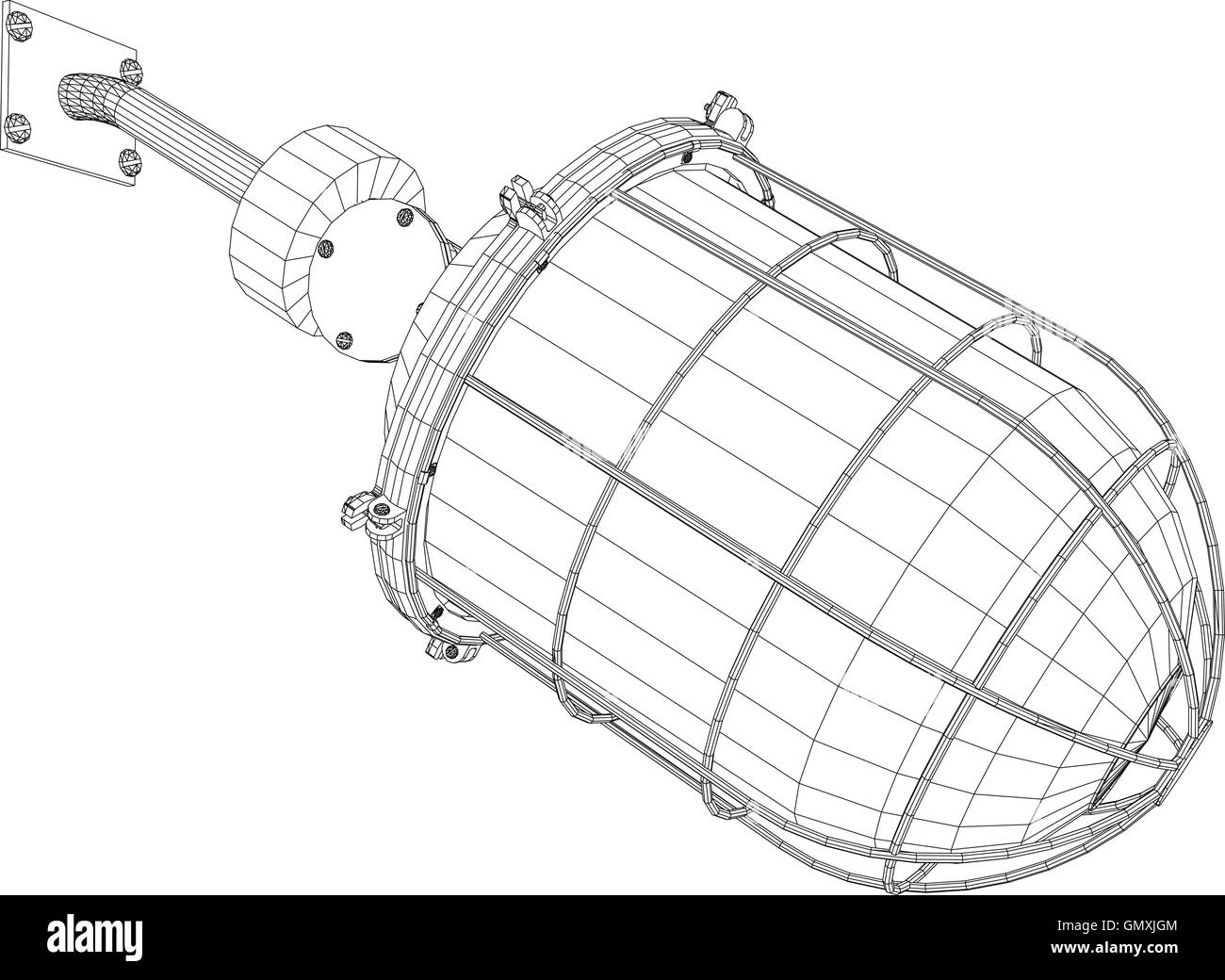

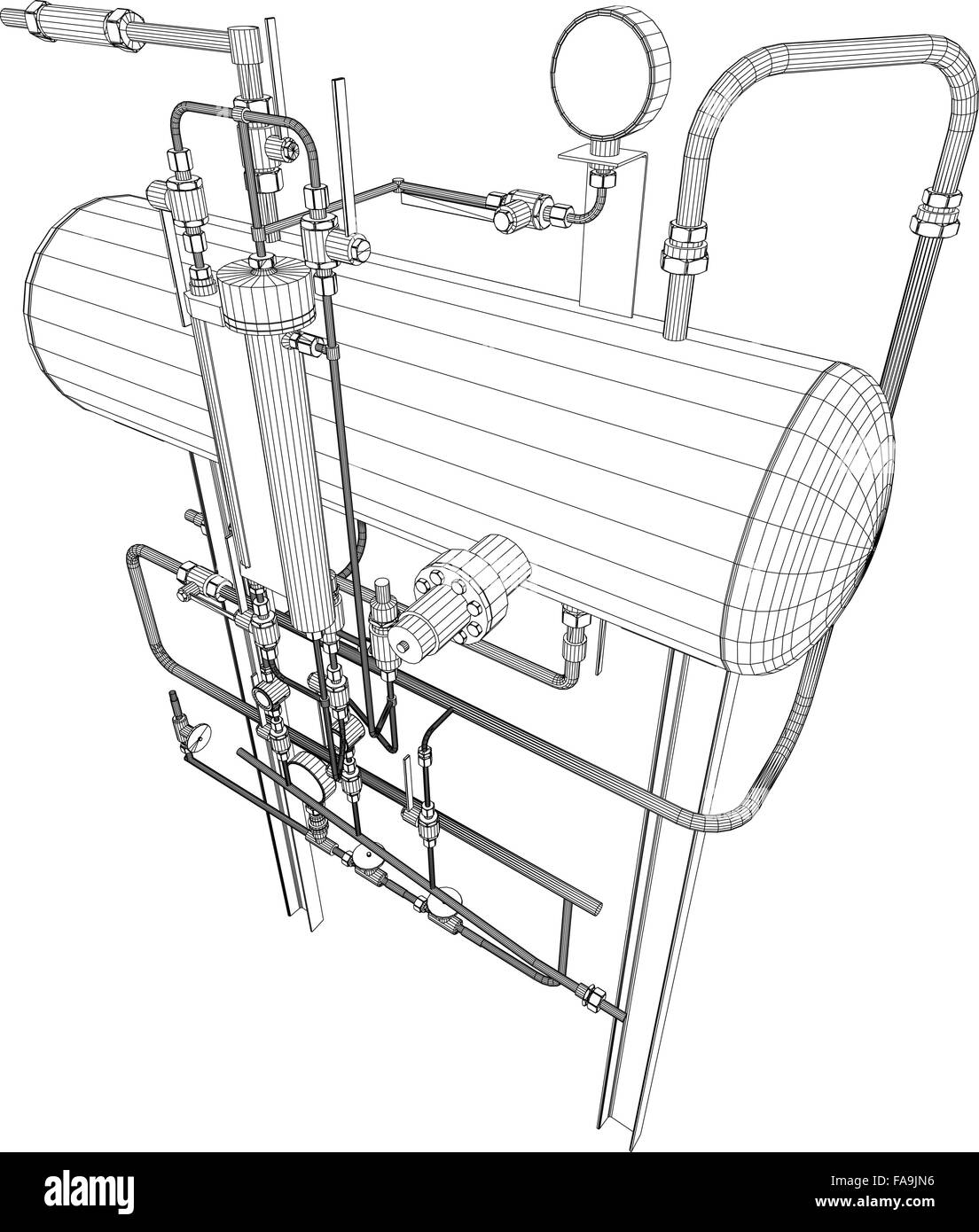

Construction of heat exchanger Stock Vector Image & Art Alamy

Scetch of heat exchanger Stock Vector Image & Art Alamy

Heat Exchanger D9A2A D9575, D9A2B D9575, D9A2C, D9A2D, D9A2E, D9A2F, D9A2G, D9A2H, D9A2J

What is A Heat Exchanger And Why Does it Matter

Covid19 Lockdown Projects Extracting Diesel Heater Exhaust Waste Heat Experimental Engineering

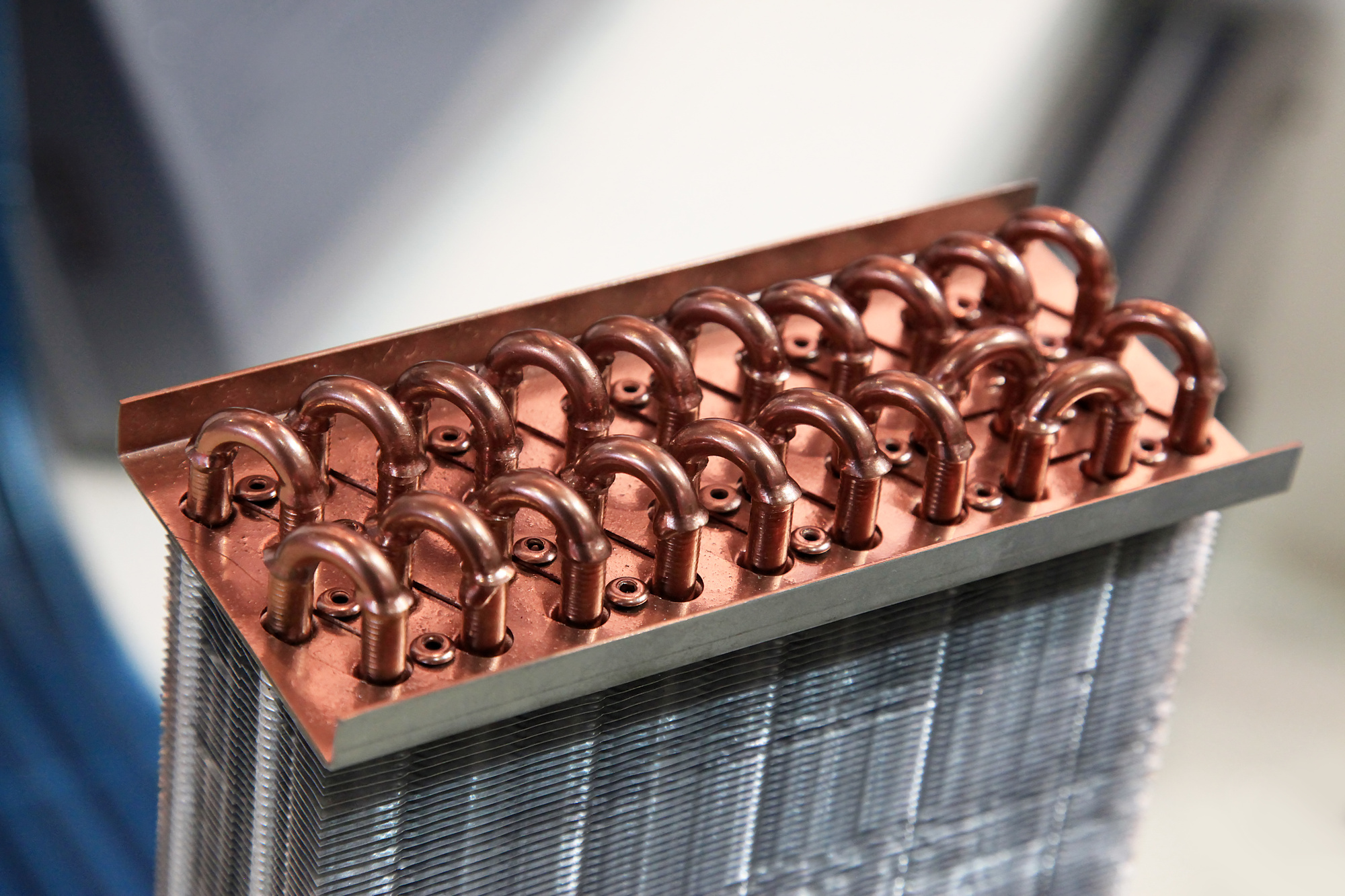

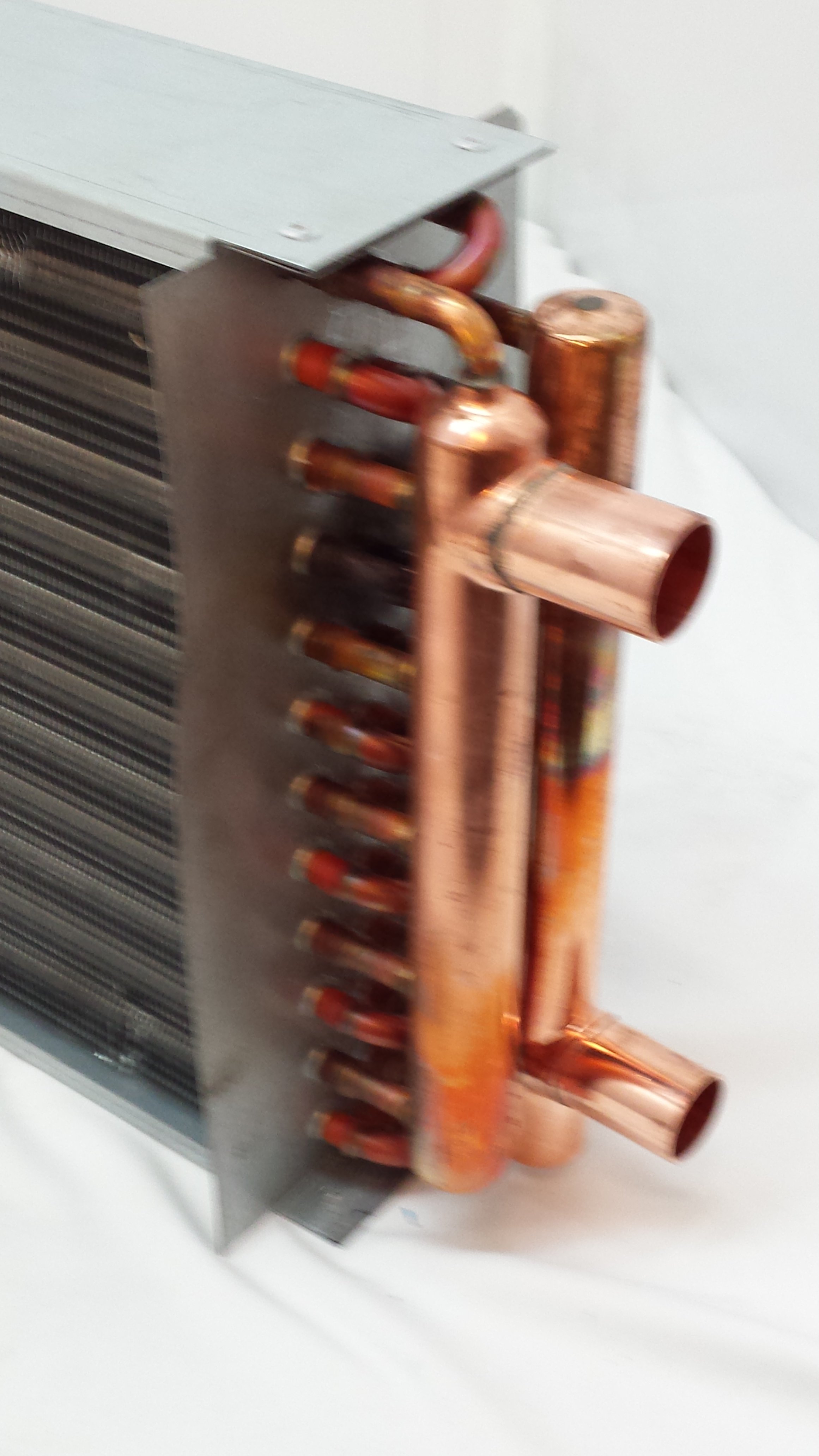

18×22 Water to Air Heat Exchanger 1″ Copper Ports with install kit The Log Boiler

Pin on Cabin

D.I.Y. Woodstove Heat Exchanger Wood Stove Heater, Diy Wood Stove, Wood Diy, Stove Oven

Woodstove Heat Exchanger 11 Steps (with Pictures) Instructables

mechanical engineering Arithmetic and Log mean temperatuer difference of a double pipe heat

Learn About Off Grid Water Heater Systems

Sanitary Heat Exchanger (18″) Cannasol Technologies

Homemade Wood Stove Hydronic Radiant Heat Setup — Heating Help The Wall Water heater diy

Oct 26, 2021. #3. Probably £2,000 / £2,500 at a rough estimate to do what you’re needing. Get swamped with daft requests for twinning stoves with boilers. 99% disappear when I say it will be over £2,000 to sort. Reply to SimonG.. Recuperative burners can be used in high temperature processes (700 -1100 °C). Regenerative burners operate in pairs and work on the principle of short term heat storage using ceramic heat regenerators. They recover between 85 -90 % of the heat from the furnace waste gases; therefore, the incoming combustion air can be preheated to very high.